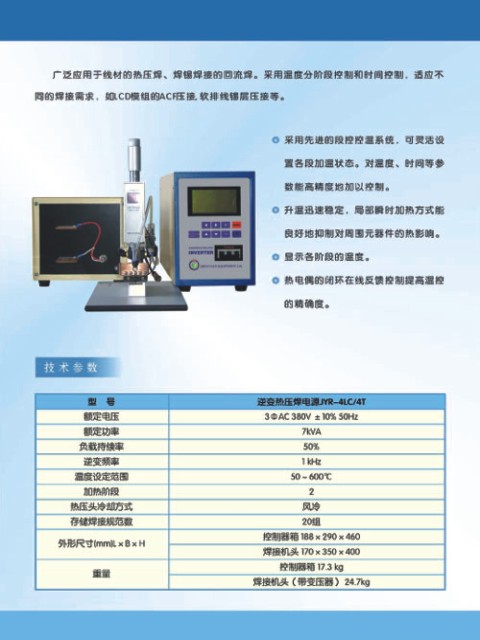

逆变精密热压焊接机

逆变精密热压焊接机 HOT BAR

广泛应用于线材的热压焊、焊锡焊接的回流焊,IC贴片。采用温度分阶段控制和时间控制,适应不同的焊接需求,如:LCD、触摸屏等的扁平电缆热压接合及ACF接合,继电器、打印机、眼镜等的树脂热压接合,手机、数码相机使用的CCD、CMOS的焊锡接合,电脑、USB、摄像机内的FPC等扁平电缆的焊锡接合,硬盘(HDD)等漆包线的焊锡焊接及DVD、AV机器等家用电器的制造。

1、采用先进的段控控温系统,可灵活设置各段加温状态。对温度、时间等参数能高精度地加以控制。

2、升温迅速稳定、局部瞬时加热方式能良好地抑制对周围元件的热影响。

3、显示各阶段的温度。

4、热电偶的闭环在线反馈控制提高温度的精确度。

5、焊接压力、焊接时间、焊接温度可精确调节。

6、可存贮20组焊接参数更换产品时非常方便。

7、多个焊点一次完成,效率高、一致性好、焊接强度高、焊点美观、操作简单。

8、10万次的焊头寿命,为贵客户创造价值.

特别适用于FPC TO PCB / HSC(斑马纸) TO FPC(柔性线路板)/ HSC TO LCD /TAB TO PCB 斑马条TAB等产品的焊接.

HOT BAR

The hot wire is widely used in welding, solder reflow soldering. The use of temperature control and time control in stages to meet the different needs of the welding, such as: LCD, touch screen, such as pressing the flat cable bonding and ACF bonding, relays, printers, optical and other hot-pressing bonding resin, cell phones, digital cameras use CCD, CMOS the solder joint, computer, USB, camera, etc. within the flat FPC cable solder joint, the hard disk (HDD), such as solder wire welding and the DVD, AV equipment, such as manufacturing.

1, the use of advanced temperature control system control segment, given the flexibility to set the temperature state of the paragraphs. Temperature and time parameters can be controlled accurately.

2, the stability of the rapid warming, local transient heating can be a good way to curb the surrounding heat-affected components.

3, the closed-loop thermocouple feedback online to improve temperature control accuracy.

4, welding pressure, welding time, welding temperature to precisely regulate.

5, can store 20 groups of welding parameters very convenient replacement products.

6, more than one-spot, high efficiency, consistency, and high strength welding, solder joint appearance, simple operation.

7, welding the first long service life.

Especially suitable for FPC TO PCB / zebra paper TO FPC / HSC TO LCD / TAB TO PCB Article zebra TAB welding products.